WaldrichSiegen Heavy Machine Technologies

Be the Market Leader Today with the Technology of Tomorrow

With the use of modern technologies and digital solutions to significantly increase the production processes, efficiency and performance of its production, WaldrichSiegen has repeatedly asserted itself against the competition on the international market.

Optimally adapted to the application process, the portal milling machines from WaldrichSiegen have been setting standards on the market for almost 200 years. The high-quality machine components, the excellent workmanship combined with an outstanding design for challenging geometric accuracies, even with increased chip volumes, make the portal milling machines from WaldrichSiegen the non-plus-ultra for demanding and precise mold making.

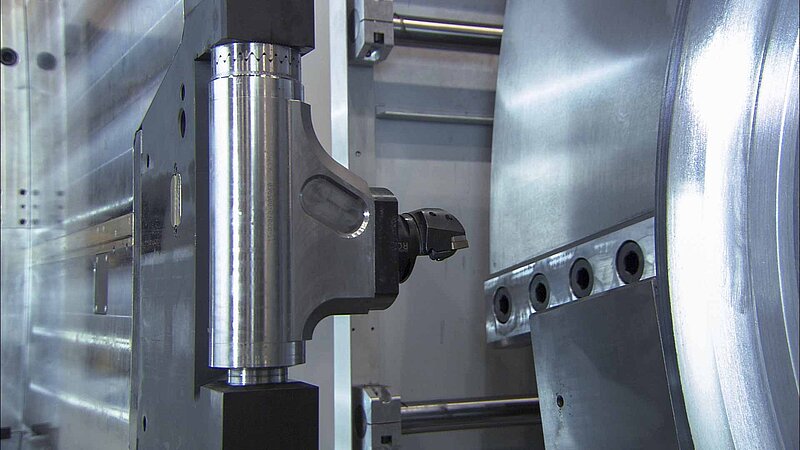

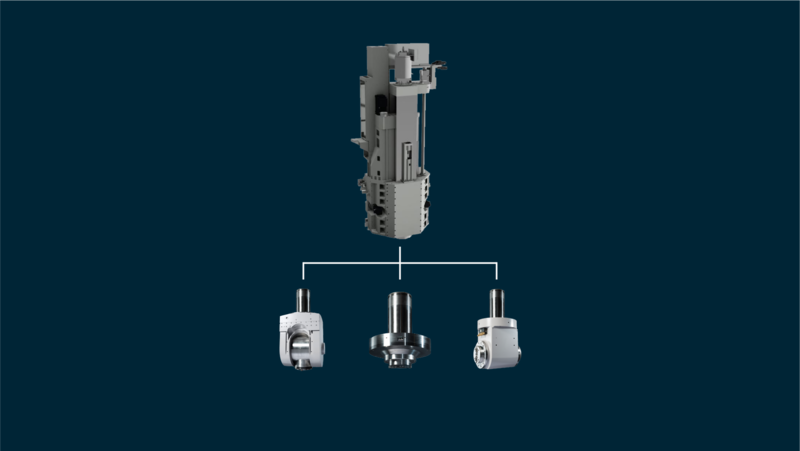

Master Head Concept

- Extreme stiffness and high damping of the milling and drilling unit

- High cutting forces are optimally absorbed thanks to stable cast construction

- No built-in headstock (RAM) // Preloaded headstock (RAM) for thermal stability and optimum compensation of deflection

- Greater rigidity and therefore less elastic deformation thanks to preloaded headstock of the crossbeam

- Built-in/integrated C-axis for quick and easy positioning of all attachments

- Dynamically balanced main drive motor optimally prevents vibrations

- Optimum adjustment of the speed range thanks to two-stage gearbox

- Hydrostatic guidance of the headstock (RAM)

- Headstock housing with high wall thickness to prevent interference and vibrations during demanding cutting operations

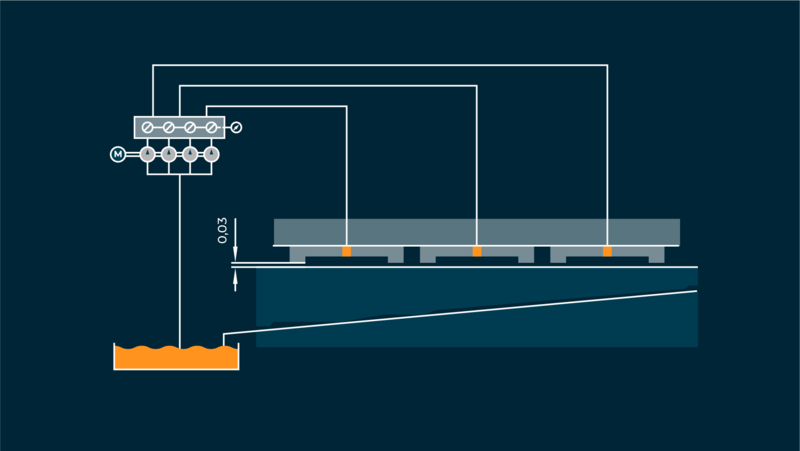

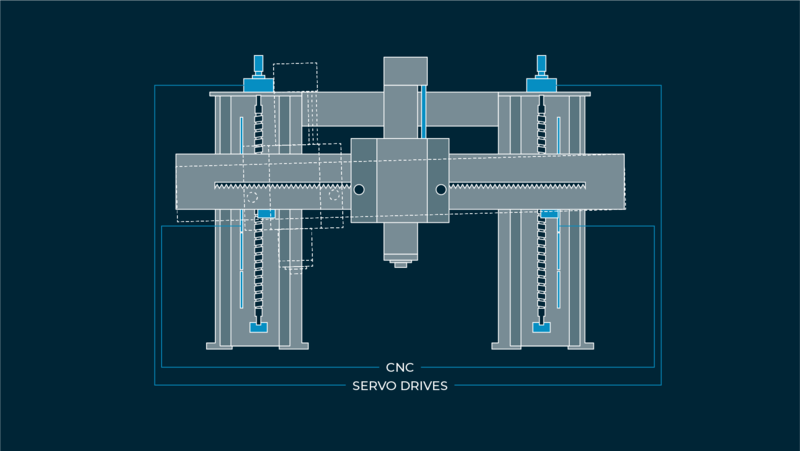

Fully Hydrostatic, Simultaneously Running Guideways in All Machine Axes

Reduced vibrations, optimum load distribution, minimal friction, no stick-slip effect and low wear for enormous machining accuracy.

Downtimes are drastically reduced and the longevity of the machine is increased.

Automatic Cross Rail Leveling (ACL) in the W-axis

automatically detects irregularities in the machine position and adjusts the crossbeam accordingly to ensure optimum parallelism to the workpiece surface.

Heel Clearance in Vertical and Horizontal Direction

enables friction-free and precise movement of the moving parts and contributes significantly to the efficiency and durability of the machines as well as absolutely precise workpiece machining within the required tolerances