Leading Technological Developments

Precision, performance, reliability - these are the strengths that make WaldrichSiegen sanding and texturing machines stand out on the market. Continuous further development, always geared to the changing requirements and challenges of the market, has made us the technology leader.

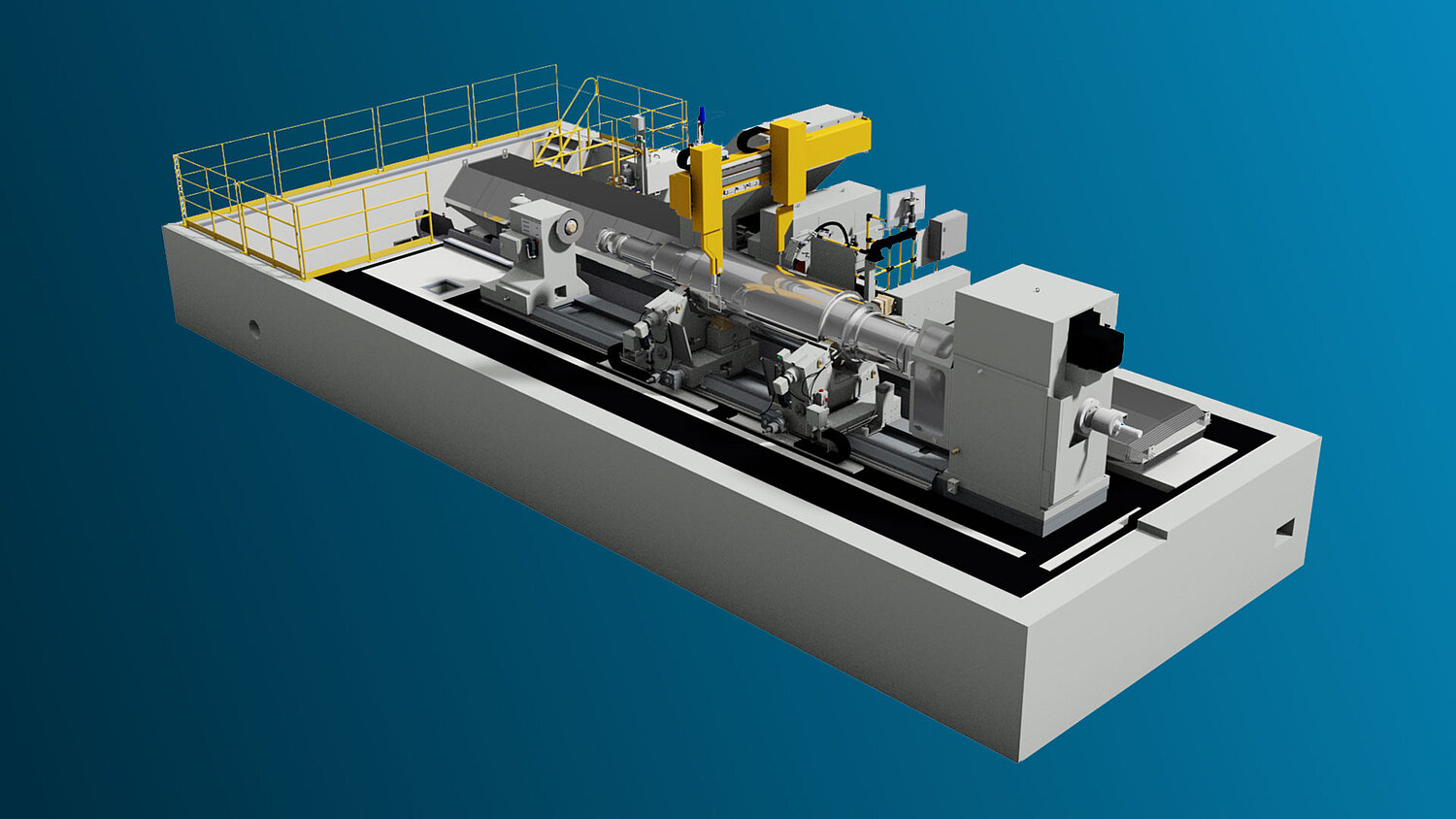

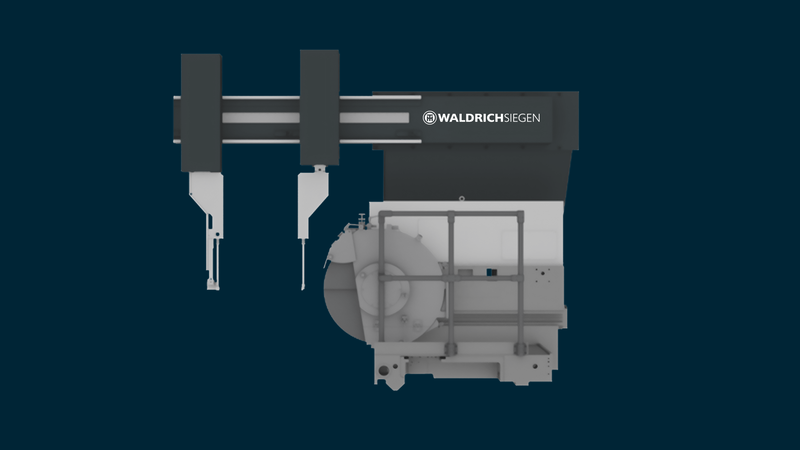

Roll Grinding Technology

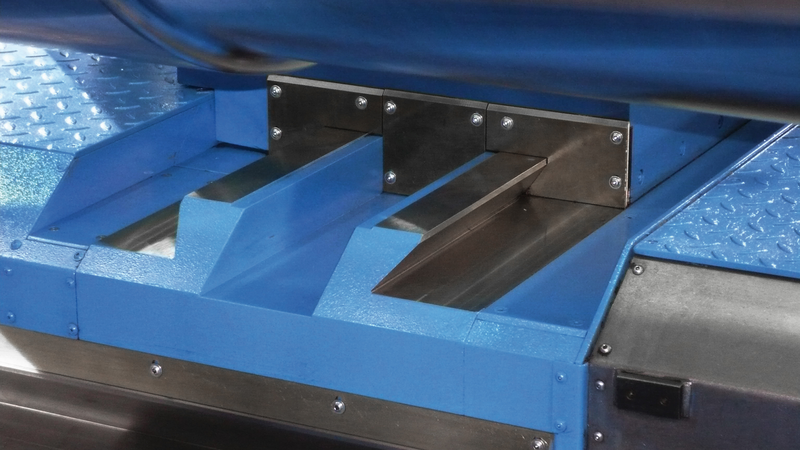

X-Axis With V-Shaped Guideways for Precise Guidance of Moving Components

- Precision and high stability and accuracy in movement

- Self-centering for greater running accuracy and adjustment of moving parts

- Low wear and increased component service life

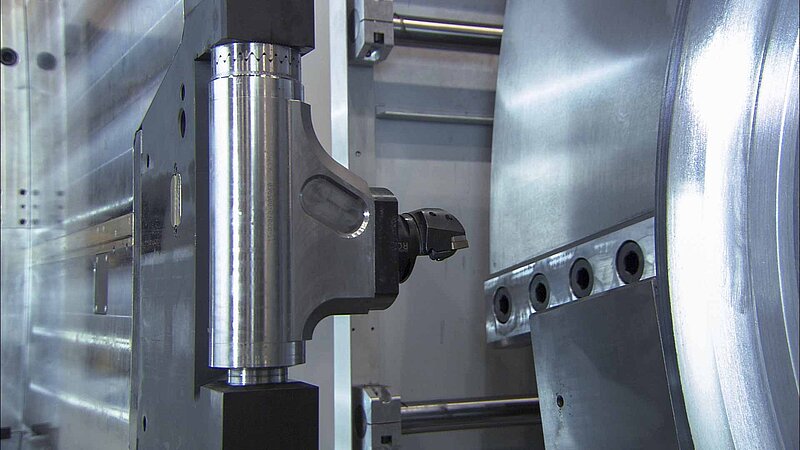

Grinding Carriage B Axis

- The B axis integrated into the grinding carriage guarantees tremendous precision at maximum cutting forces and stock removal rates along the roll geometry.

- Eccentric grinding axis bearing for optimum machining of complex geometries

- Guarantees consistently high surface quality of various cam shapes from infeed increments as small as 0.0001.

- Highest accuracy of the infeed increments of 0.0001

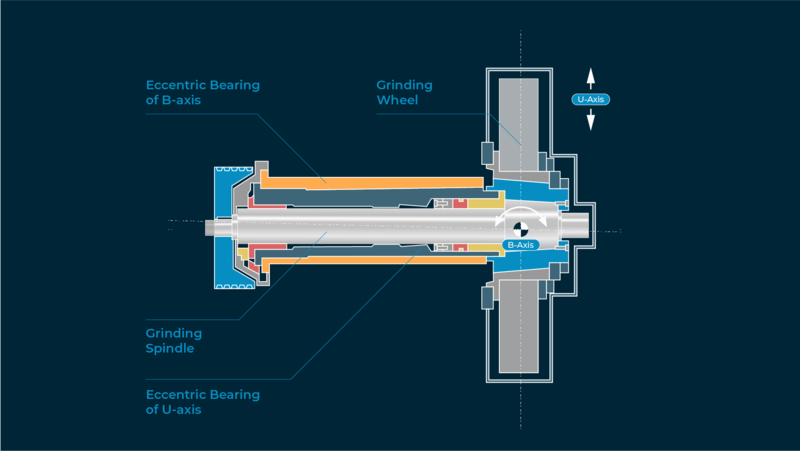

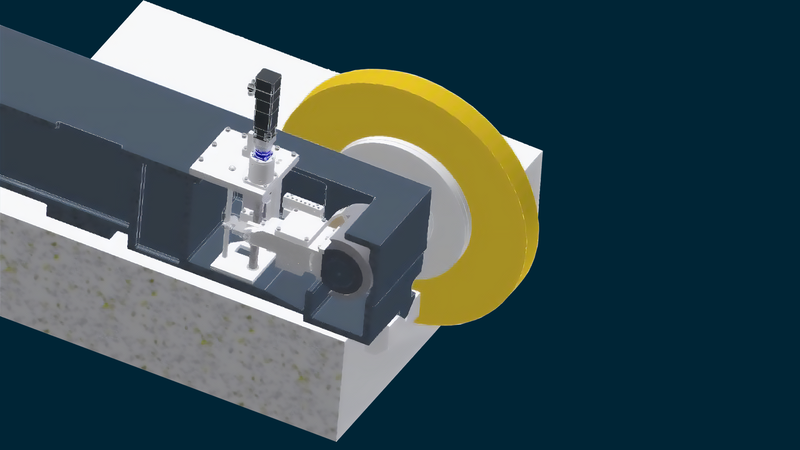

Fine Infeed of the U Axis

The stable and low vibration “monoblock” wheel head design with eccentric hollow shaft ensures a high degree of positioning accuracy. The design ensures that the grinding wheel is aligned to the roll with high precision, especially in the X axis (i.e., the horizontal axis), which makes precise machining and uniform wear of the grinding wheel possible.

Two-Point Measuring System

The two-point measuring system from WaldrichSiegen provides the geometric measurement data of the rolls. It measures the roll with great precision with 360 measured values from stock removal and diameter to shape, roundness, and eccentricity per revolution. The measurements are taken both before and during the grinding process.

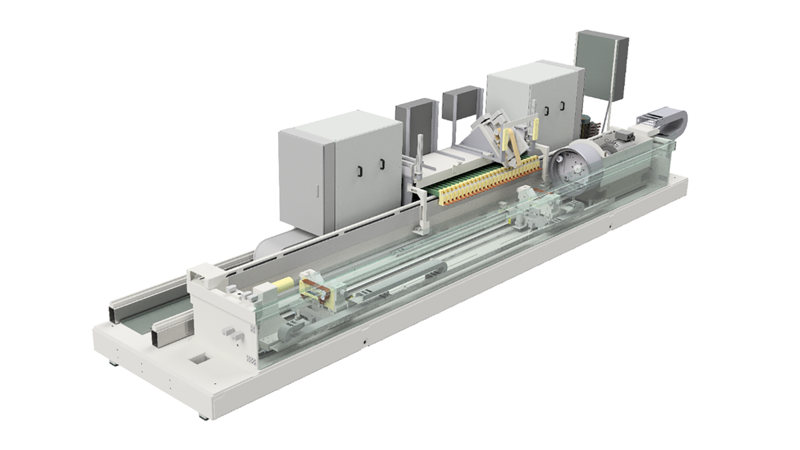

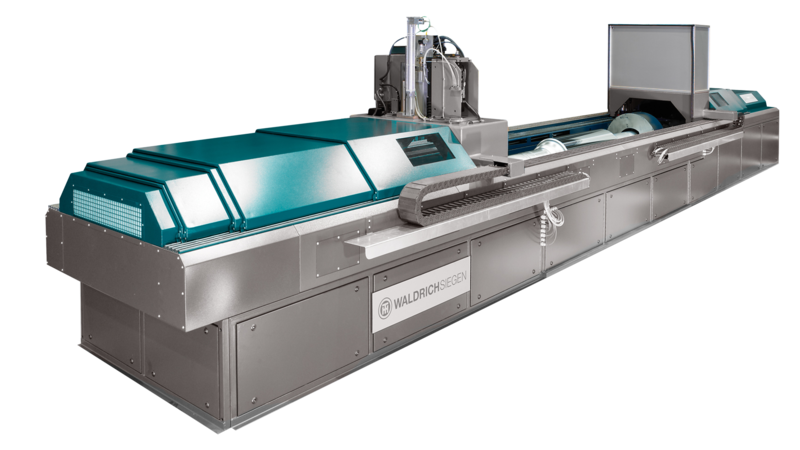

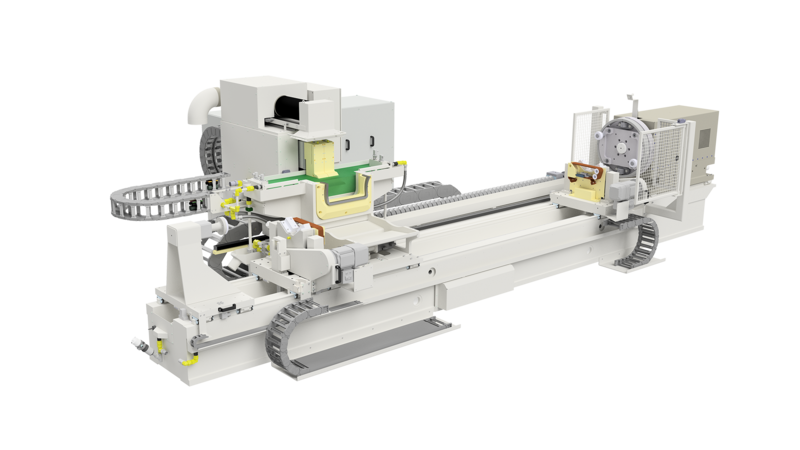

Roll Texturing Machines (EDT)

Tailor-Made Solutions With Maximum Performance and Flexibility

Availability of 3 machine types for different texturing requirements - The most suitable machine type for every customer's needs:

- ProfiTex 60S Single-row EDT machine with 30 electrodes

- ProfiTex 30 / 60 EDT machine as single-row or double-row machine (up to 60 electrodes)

- Compact design PTM 500 EDT-Maschine with up to five texturing heads with 16 electrodes each

Machine comparison table

| Machine type | PT 60S | PT 30/60 | PTM 500 |

| Number of electrodes | Up to 30 |

| Up to 5 heads with 16 electrodes each |

| Capacity | Up to 550 rollers per month | Up to 1,100 rollers per month | Up to 800 rollers per month |

| Texturing process | Electrodes are vibrating | Electrodes are vibrating | Electrodes are moved along the roller bale using the side-shift function |

| Setting the electrodes | Each electrode can be aligned | Each electrode can be aligned | Each head can be aligned |