The horizontal boring mills of the UNION brand are used worldwide wherever absolute precision and efficiency are required and quality compromises are not an alternative. WaldrichSiegen is responsible for the development, production and distribution of UNION quality products within the globally active HerkulesGroup.

Precision Horizontal Boring Machines

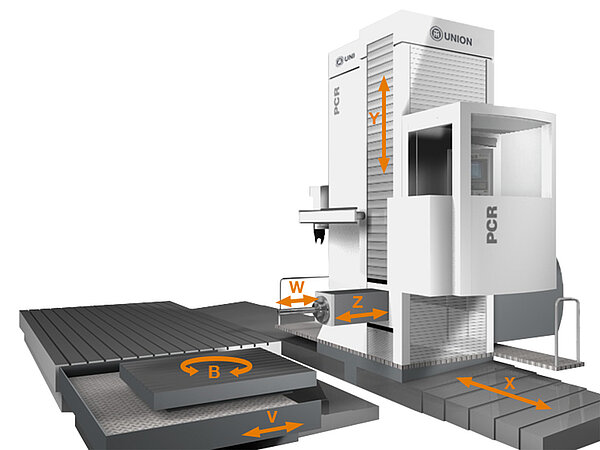

with Floor Plate P/PR-Series

The P-series machines are high-precision horizontal boring and milling machines in floor plate design for reliable machining of medium-sized workpieces. From stable heavy-duty roughing to precise surface finishing, the P-series is the ultimate in efficient 5-sided machining.

The PR-series boring mills in floor plate design with RAM are especially powerful and the first choice for large workpieces with XXL dimensions up to 40 m long and 10 m high.

Technical Data

Maximum Performance and Precision

W (Boring Spindle)

up to 1,500 mm

X (Column, transverse)

up to 40,000 Nm

Y (Column, vertical)

up to 10,000 Nm

Z (RAM)

up to 2,000 mm

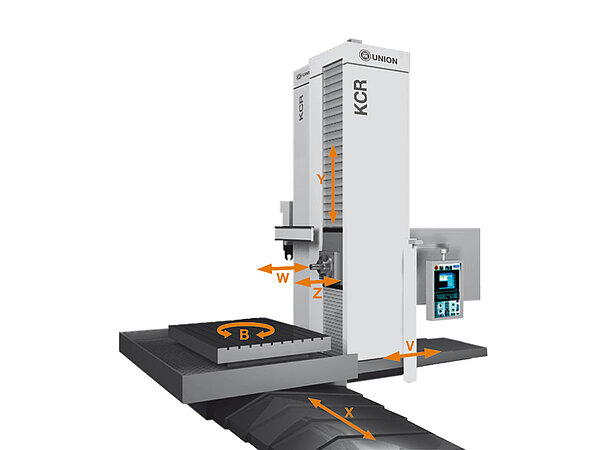

K-Series Boring Mills and

KG-Series Precision Boring Mills

in Planer Design

The reliable K-series machines enable efficient complete machining of prismatic workpieces up to a size of 6,000 × 4,000 × 2,000 mm. They are available with automatic tool changer, pallet changer, different table assemblies, milling head changer or integrated NC facing head and can therefore be used universally for any application. The KR 150 is designed with a hydrostatically guided RAM with an additional infeed axis (Z). The superimposition of the columns and the movement of the RAM results in the most stable cutting conditions up to the center of the table.

The UNION Precision Boring Mill KG in planer design represents the highest level of precision and is the solution for all users who have to manufacture and machine to the tightest tolerances. Complex, prismatic workpieces with dimensions up to 2,000 × 1,600 × 1,500 mm and weights of up to 6 t and more are machined with high precision.

Technical Data of the K-Series

Maximum Performance and Precision

X (Table, transverse)

up to 6,000 mm

Y (vertical)

up to 4,000 mm

Z (Ram longitudinal)

up to 1,100 mm

V (Column longitudinal)

up to 3,500 mm

W (Boring spindle)

up to 1,000 mm

Industries

For Complex and Individual Requirements

WaldrichSiegen is your expert partner for innovative, customer-specific machine solutions. We design customized machines according to the latest state of the art and the highest quality standards for all industries.

- Mining

- Energy & Wind Technology

- Automotive Industry

- Contract Manufacturing

- Machine & Plant Engineering

- Pumps & Compressors