Complex Complete Machining in a Single Set-Up

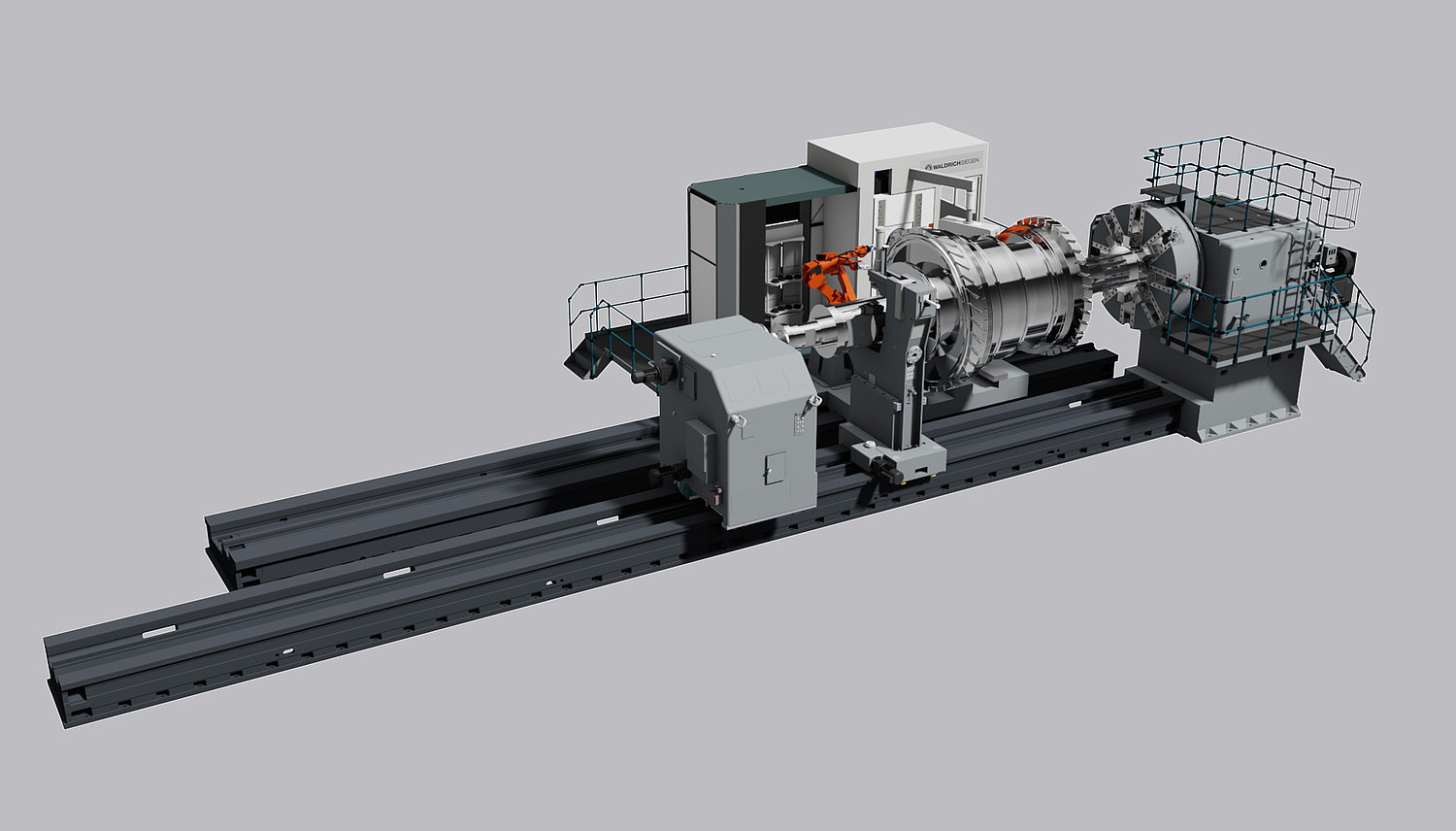

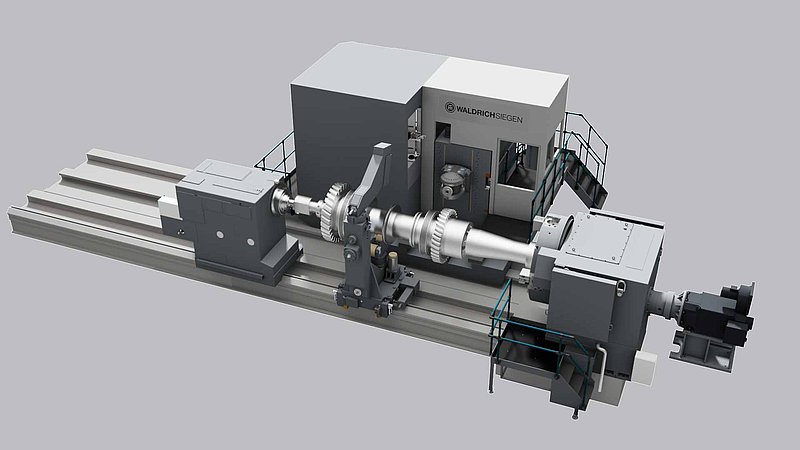

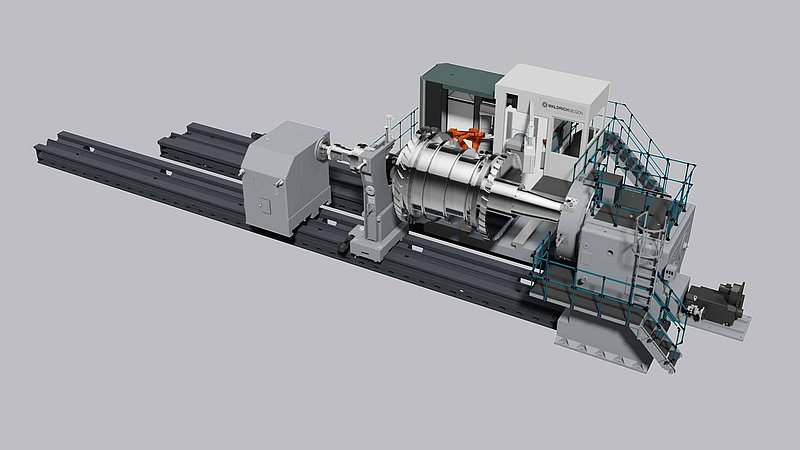

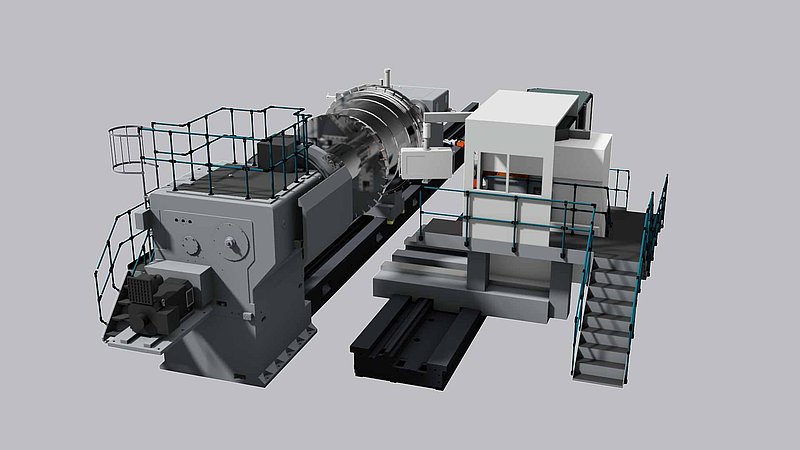

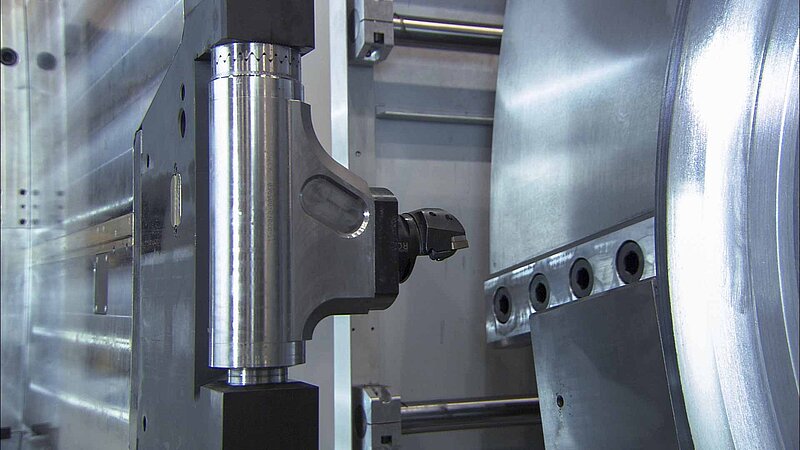

The mill-turning machine ProfiTurn M has been designed specifically for the complete machining of complex, rotationally symmetrical workpieces. Both turning and milling units, as well as boring and grinding units can be attached to the Masterhead interface located at the milling tower. The result is highest efficiency. All stages of the machining process are performed on a single machine and multiple set-ups, which are both elaborate and costly, are reduced.

Whether turbine or generator rotors or heavy forged parts – the ProfiTurn M has been developed for the precise and efficient machining of demanding workpieces with a diameter of up to 4.2 m, a length of 25 m and weights between 20 and 250 t. The machine is characterized by an overall concept that is both operator and maintenance-friendly and by its energy efficiency.

Technical Data

For Highest Precision and Performance

Torque

up to 7.000 Nm

Workpiece weight

up to 250 t

Milling power

up to 80 kW

Workpiece diameter

up to 42.000 mm

Industries

For Complex and Individual Requirements

WaldrichSiegen is your expert partner for innovative, customer-specific machine solutions. We design customized machines according to the latest state of the art and the highest quality standards for all industries.

Machine Technology

Modular Concept for Custom-Fit Machines

The ProfiTurn M from WaldrichSiegen impresses with its reliable stability and modular concept. Each machine is individually designed to meet the customer's requirements. The extremely rigid box-in-box design of the milling tower guarantees maximum stability even with high cutting forces.