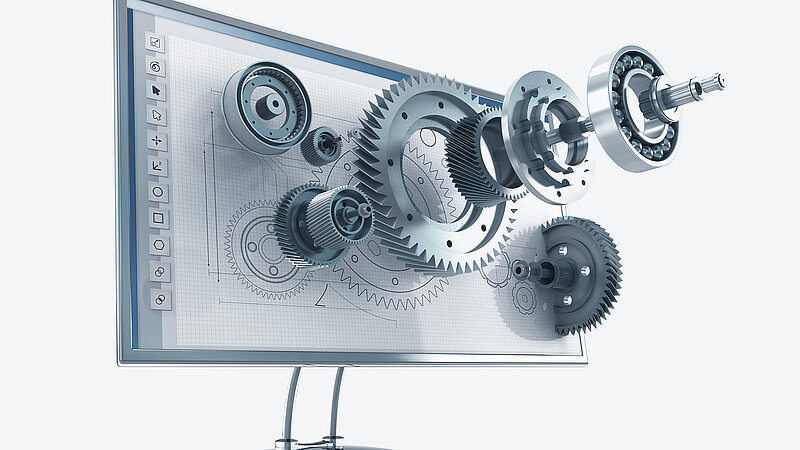

ProfiTurn H Turn-Milling Operations

Maximum Productivity on a Single Machine

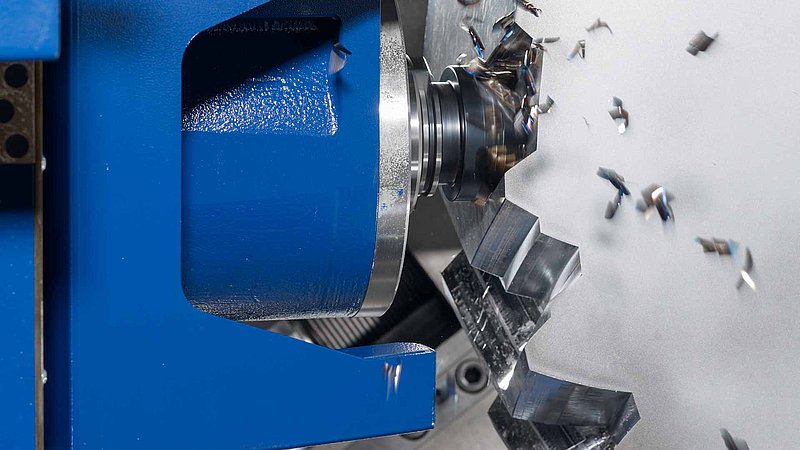

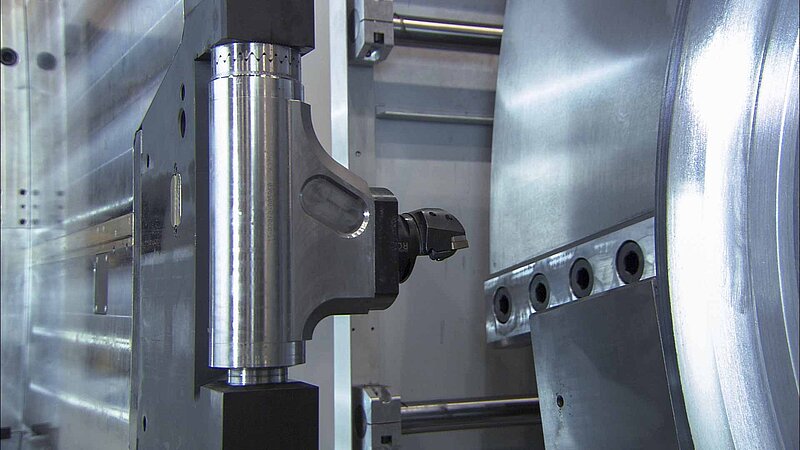

Highest precision in turn-milling operations is achieved by extreme stiffness of the machine structure. Therefore, ProfiTurn Hmachines feature a very rigid design. All major components are made of cast iron and are manufactured in-house with the highest tolerances. The guideways of the machine are consistently hydrostatic in order to guarantee the accuracies, the reliability, and the long life-time WaldrichSiegen machines are known for. A milling unit pivoting by 95° has been integrated into the carriage in order to ensure both turning and milling operations with ProfiTurn H. Rough machining and finish machining can be carried out on one single machine. The ProfiTurn H machines feature maximum flexibility and a high degree of process integration..

Technical Data

For Highest Precision and Performance

Torques

up to 120.000 Nm

Workpiece weights

up to 150 t

Workpiece lengths

up to 20.000 mm

Power

up to 310 kW

Industry Solutions

For Complex and Individual Requirements.

WaldrichSiegen is your expert partner for innovative, customer-specific machine solutions. We design customized machines according to the latest state of the art and the highest quality standards for all industries.

Performance Data

Turning and Milling on One Machine

A milling unit pivoting by 95° has been integrated into the carriage in order to ensure both turning and milling operations with ProfiTurn H. Rough machining and finish machining can be carried out on one single machine. The ProfiTurn H machines feature maximum flexibility and a high degree of process integration.