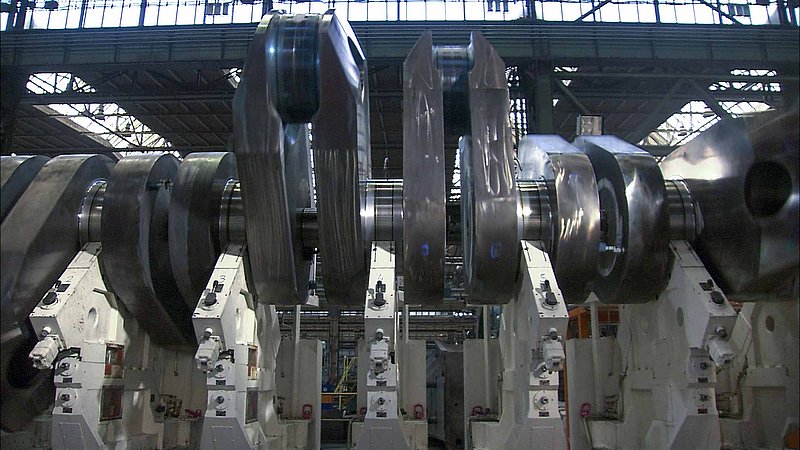

Crankshaft Turning ProfiTurn H

Economical Machining of Crankshafts, Large Crankshafts and Eccentric Shafts

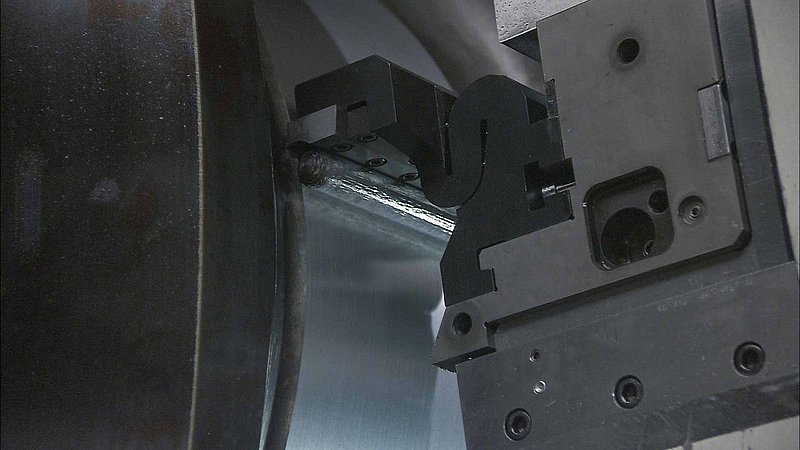

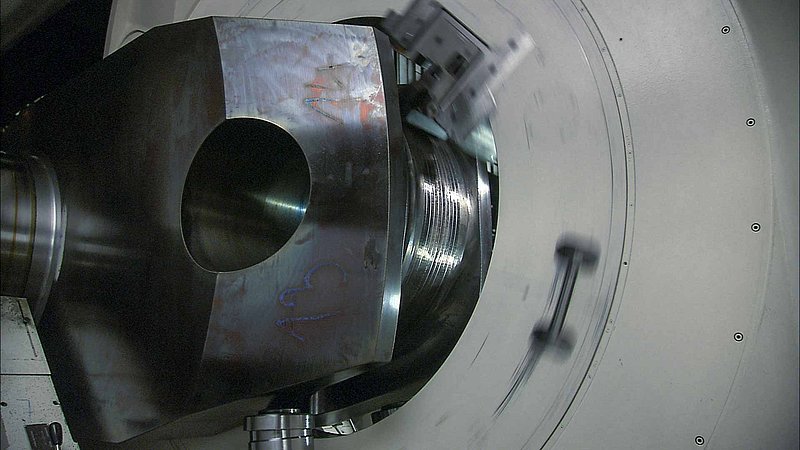

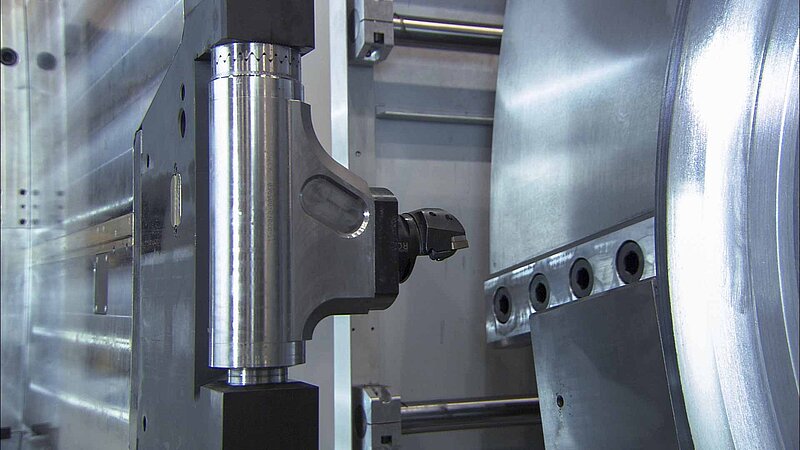

WaldrichSiegen attaches great importance to a rigid design and maximum stiffness of the overall machine structure. In principle, crankshaft machines of the ProfiTurn H series are equipped with hydrostatic guideways in all linear axes providing for high wear-free operation, as well as, excellent damping characteristics.

Productivity and efficiency of these crankshaft lathes can be increased with the so-called twin or double carriage concept developed by WaldrichSiegen. Approximately 70 % of the total processing time of a crankshaft is needed for machining the main bearings. In the twin concept the two workpiece sides of a twin crankshaft lathe make joint usage of a pin turner and thus provide for maximum machine utilization at reduced investment costs.

Technical Data

For Highest Productivity and Efficiency

Torque

up to 400.000 Nm

Workpiece weight

up to 500 t

Workpiece length

up to 30.000 mm

Power

up to 500 kW

Industries

For Complex and Individual Requirements

WaldrichSiegen is your expert partner for innovative, customer-specific machine solutions. We design customized machines according to the latest state of the art and the highest quality standards for all industries.

Machine Technology

Technology Tailored to Your Needs

In principle, crankshaft machines of the ProfiTurn H series are equipped with hydrostatic guideways in all linear axes providing for high wear-free operation, as well as, excellent damping characteristics.