Industries

Tailor-Made Solutions for Every Demand

From plate mill via paper industry through engine manufacturers – every industry has its own needs and has to fulfill special requirements. WaldrichSiegen takes this feature into account by producing high quality machines that are designed for permanent precision.

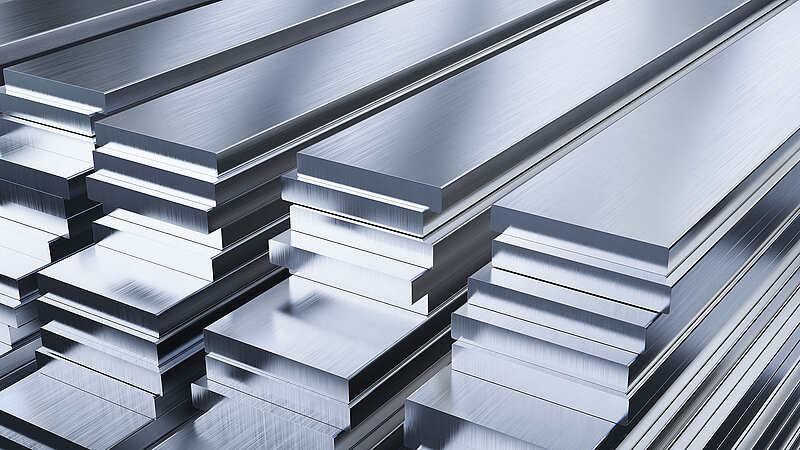

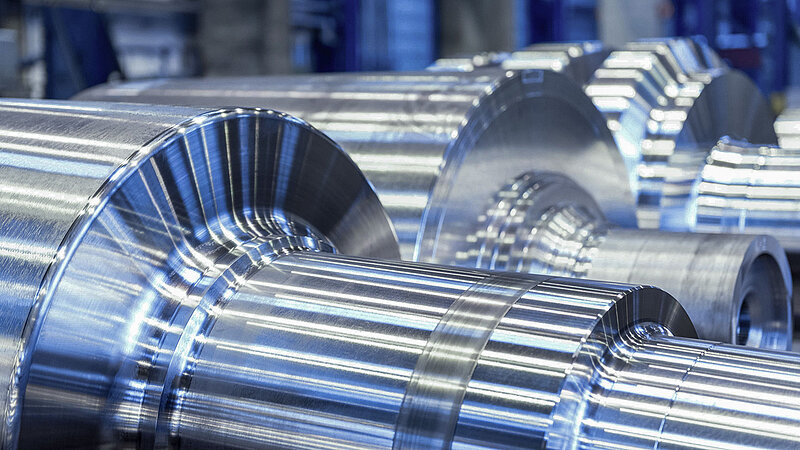

Aluminum Industry

The production of flat products made of aluminum at cold and hot rolling mills requires the highest precision and meeting of the closest tolerances. First class rolls are the precondition for high manufacturing qualities. Only rolls with perfect barrel geometry and roughnesses guarantee a high quality of the end product.

Stainless Steel Industry

Highest quality of sheet metals – manufacturers of stainless steel have to face this challenge day by day. Their customers have the highest expectations regarding the surface quality, the paintability and the deep drawing properties of the metal sheets. Even the smallest defect on the roll may ruin the end product – here the principle "quality right from the beginning" is of upmost importance.

Energy Technology

Especially in the power industry, it is extremely important to manufacture workpieces efficiently and with cost- effectiveness.

Plate Mill

The more precise the grinding processes in the plate mill, the better the quality of the finished products. The tallest rolls in the scaffold that arise from the market are used for roll widths of 6.000 mm and slab thicknesses up to 350 mm.

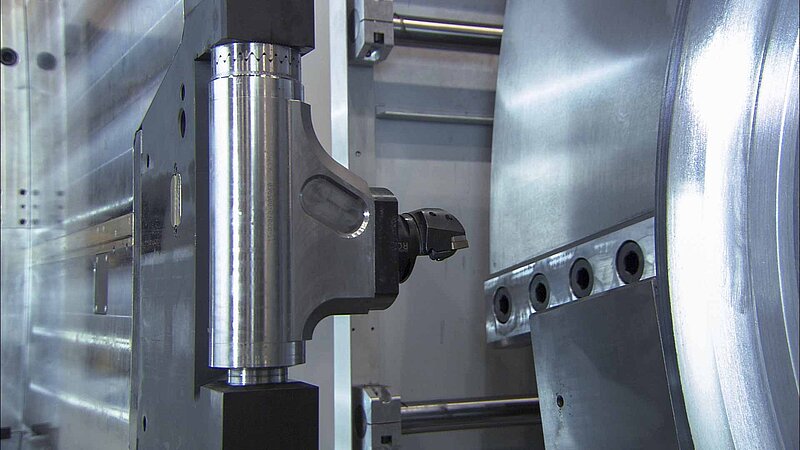

Engine Manufacturers

Manufacturers of gas and diesel motors, whether 2 or 4 stroke, have to face special challenges regarding productivity and precision. Especially manufacturers of 2 stroke diesel motors for ships have to machine tall and complex workpieces like marine crankshafts and engine housings with the highest accuracies. Only the use of extremely powerful and wear free machine tools allows for such demanding tasks.

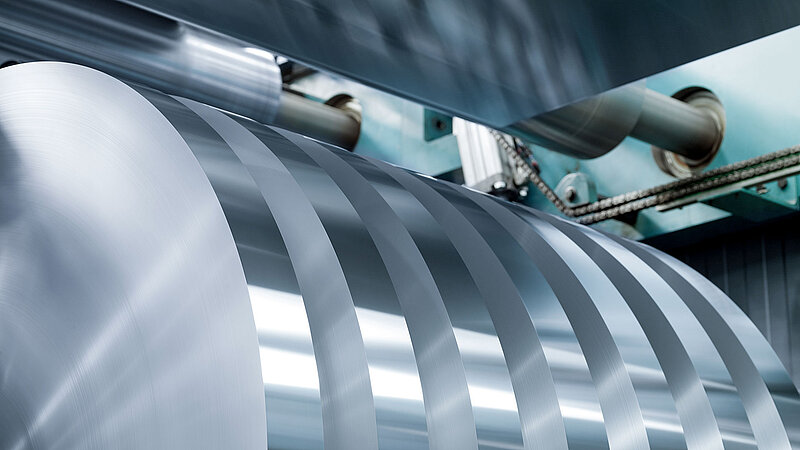

Cold Rolling Mill

Reproducible roll barrel geometries and a faultless surface are essential for flawless products and a continuously high manufacturing quality in the cold rolling mill. The basis for high quality end products is provided by WaldrichSiegen roll grinding and electrical discharge texturing machines worldwide.

Paper Industry

Speeds of more than 2,000 m/min, constantly decreasing layer thicknesses and increasingly thinner paper qualities – the paper industry has to fulfill extremely high requirements. This calls for the highest quality and selection with regard to the related paper roll grinding machines: They have to be designed for the machining of tall roll widths and roll diameters, high weights, as well as, a wide range of roll types with different coatings.

Non-Ferrous-Industry

The absolutely highest surface quality of a roll is indispensable in the production of high grade copper and brass foil. End products with a thickness of 6 µm do not forgive the slightest mistakes or irregularities. These would inevitably lead to a loss of quality.

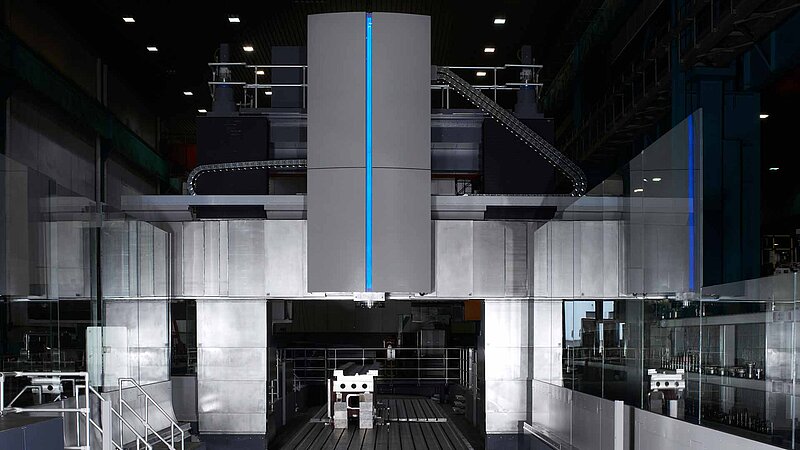

Forges & Foundries

In forges and foundries machine technology has to perform at its maximum efficiency. Here a high cutting capacity and availability are of the first priority even in difficult environments. Especially the roughing operation requires extremely powerful machines.

Heavy Mechanical Engineering

Powerful and precise machine tools that guarantee the highest availability and a reliable machining of all workpieces play a key role at the machining of components for heavy machinery. Just as important, is the capability to adjust the machines individually to specific cases.

Service Center

Efficient machines that prove to be of the highest reliability and short processing times are an essential factor for service centers. This is the only way to guarantee an efficient processing of the rolls.

Customized Machine Engineering

WaldrichSiegen is considered a specialist regarding specific solutions for difficult applications worldwide. No matter which industry or application – the application engineers of WaldrichSiegen develop a machine concept and a machining strategy for each workpiece – no matter how complicated it may be.

Roll Manufacturers

For the machining of forged or cast rolls for flat or long products – WaldrichSiegen grinding and turning machines permanently guarantee outstanding results at the machining of the biggest rolls with a weight of more than 300 t and a diameter of more than 3,000 mm. Roll manufacturers worldwide acknowledge the extremely high cutting performance of WaldrichSiegen ProfiGrind and ProfiTurn H machines for grinding and turning.

Hot Rolling Mill

Faultless rolls are the key to a first class manufacturing quality in the field of hot strip. Most defects arise from deficient rolls. Profile deviations, exorbitant thickness tolerances or surface defects on the strip cannot totally be compensated in the subsequent steps and may cause a degraded result.

Mining

The construction and maintenance of heavy machinery and processing plants for opencast and underground mining often require precise and fast processing of single or large parts, but also for small batch work pieces.

Automotive Engineering

Machine tools for gear and motor component processing for transport and construction vehicles or the shipping industry have to be versatile and easily adaptable. No matter whether small or medium batch production or large marine diesel engines – The workpieces, spare parts and single components have to be processed precisely and efficient in whatever state of complexity.

Contract Manufacturer

To be optimally prepared for the processing of a broad workpiece range, contract manufacturers need flexibly configurable machines which can be used for heavy and high-precision finish machining and also be programmed for all kinds of processing operations directly on-site.

Machine & Plant Engineering

Machine and plant engineers work especially with machine tools which are flexible, universally usable and precise but also easy to operate and maintain.

Pumps & Compressors

Pumps and compressors are used in many different industries and installed in numerous devices and machines. Whether in vehicles, cooling and heating systems or drinking wells – absolute precision, minimized average cost and clamping processes and the highest possible efficiency are the main factors that count during the manufacturing process.